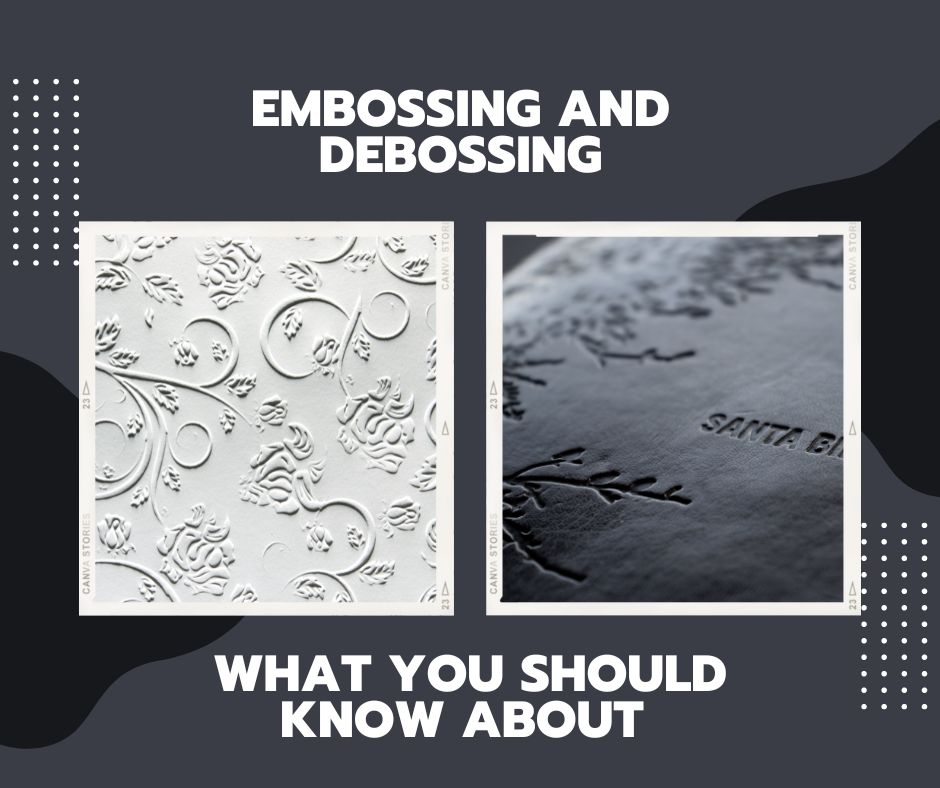

Using these procedures, paper and other materials can be embossed or debossed. The difference between an embossed design and a debossed one is the height they stand in relation to the background.

The same can be said about embossing. The terms “embossing” and “debossing” refer to two different methods of impressing or depressing an image into paper. When paired with additional print effects, like foil stamping, embossed designs may turn a fantastic piece into a luxury one. These widespread print effects are perfect for accomplishing just that.

Embossing

Using embossing, you can highlight specific details on a sheet of paper and draw more attention to them. Paperbacks with embossed covers are common. The title and author’s name are embossed to make the book more interesting.

Stock paper and a die machine are the two primary tools a professional printer uses when embossing. Like a stamp, the die is pressed into the stock to create raised designs on your printed material. A multi-level die makes a complicated raised or depressed image, while a single-level die gives your image the same height or depth.

Ultimately, your design will have a more three-dimensional look and feel, drawing attention to a specific location. Many people emboss their company logo, initials, a custom illustration, or a pattern for a classy touch.

Raised effects on paper are what most people picture when they think of embossing. Therefore, business cards, greeting cards, and invitations are common embarrassment targets. However, metal, acrylic, leather, wood, and fabric can all undergo the embossing process. This article, however, will concentrate on embossing paper, integrating embossing with other effects, and preparing your design for the greatest possible finish.

What is the process of embossing?

Embossing is done with a bespoke die. The die is explicitly carved to fit precisely within the boundaries of the design or text that will be embossed. Following this, the die machine receives the paper or covers the reverse side of the sheet facing the die. The paper or cover is pushed away from the die’s raised portion, which subsequently creates the raised effect. Take a look at this video demonstration if you’re interested in seeing the procedure in action.

Debossing

When debossing, however, sections of a sheet are lowered to create a “sunken-in” effect. This also draws the eye by reducing the prominence of one area. Debossing isn’t as common as embossing, but it can still reinforce a brand’s identity or a specific look.

Debossing is the antithesis of embossing. You can emboss a logo, text, or other images to give your printed material a subdued look. The debossed area can be left blank or filled in with ink or foil stamping, much like embossing.

Debossing allows you to use both sides of your printed piece, unlike embossing, which leaves the back unusable. It can replace embossing entirely or be used in tandem with that technique.

What is the process of debossing?

Debossing is similar to embossing in that it also requires a unique die. On the other hand, when the paper or cover is fed into the die machine, the blank side of the sheet faces the metal cutting tool. The paper or cover is pushed away from the debossed part of the die, giving the impression of a submerged design.

Printed materials with embossing or debossing stand out from the crowd. They’re the kind of business cards people can’t stop touching or wedding invites that set the tone for a day of refined sophistication. The price may be higher than usual compared to a regular print job, but it will be well worth it if the results are eye-catching and memorable print pieces that help you stand out from the crowd.